We-iTech offers wide choices of open loop and close loop stepper drives. It can control stepper motors through simple step and direction control and EtherCAT/CANbus/Modbus network.

Based on new 32-bit DSP technology, open loop stepper drive are designed for various models of 2 phase and 3 phase 28~130mm (NEMA 11~52) hybrid stepper motors which current are from 0.5A~11.2A. With servo-similar control circuit and superior software algorithm, KD series drive has superior performance in smoothness, noise and vibration. Smooth and accurate current control technology greatly reduces motor heat.

A closed-loop stepper drive can receive the encoder feedback from close loop stepper motor, so it can detect commanded target position and real-time position of the motor shaft. That’s why close loop drive can work like servo system. This closed-loop system solved the step loss problem in open loop stepper systems, but it’s cost is less than AC servo system. Therefore, We-iTech close loop stepper drives are widely used to upgrad open-loop systems, or replacing servo applicaitons which speed are within 1000RPM.

SDW60 SDW42

Based on the 32-bit DSP platform, provided with vector control technology and servo demodulation function internally and in combination with feedback from the encoder of closed loop motor, SDW60 stepper servo drive enables the stepper servo system to feature low noise, low heating, no loss of step and higher application speed, able to improve performance of the intelligent equipment system comprehensively.

SDW86

Based on the new 32-bit DSP platform, provided with vector control technology and servo demodulation function internally and in combination with feedback from the encoder of closed loop motor, SDW86 stepper servo drive enables the stepper servo system to feature low noise, low heating, no loss of step and higher application speed, able to improve performance of the intelligent equipment system comprehensively.

SDD86

Based on the new 32-bit DSP platform, provided with vector control technology and servo demodulation function internally and in combination with feedback from the encoder of closed loop motor, SDD86 stepper servo driver enables the stepper servo system to feature low noise, low heating, no loss of step and higher application speed, able to improve performance of the intelligent equipment system comprehensively.

SDD110

Based on the new 32-bit DSP platform, provided with vector control technology and servo demodulation function internally and in combination with feedback from the encoder of closed loop motor, SDD110 stepper servo driver enables the stepper servo system to feature low noise, low heating, no loss of step and higher application speed, able to improve performance of the intelligent equipment system comprehensively.

DW556-ECR

ECR series is a high-speed Fieldbus type closed-loop stepper driver based on closed-loop stepper, combined with EtherCAT Fieldbus technology. It supports COE(CANopen over EtherCAT) protocol, conforms to CiA402 standard, and the Fieldbus transmission rate can reach 100Mb/s, which can realize closed loop. The real-time control and real-time data transmission of the stepping system has the advantages of high performance, high transmission speed and high reliability communication.

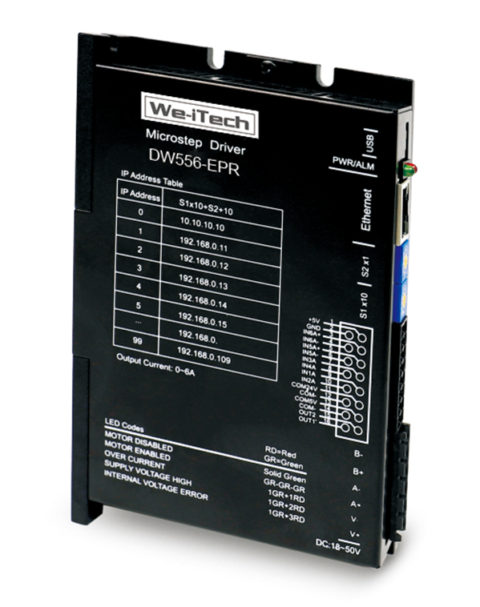

DW556-EPR

EPR series stepper motor driver is based on Ethernet technology. The driver adopt MODBUS/TCP protocol With standard ethernet interface, 10M/100M bps internet interface can be compatible. Compare with MODBUS/RTU products, the communication speed is greatly improved (highest speed of DW556-RS485 is 115200bps). With the standard Ethernet format compatible function, much cost can be saved.

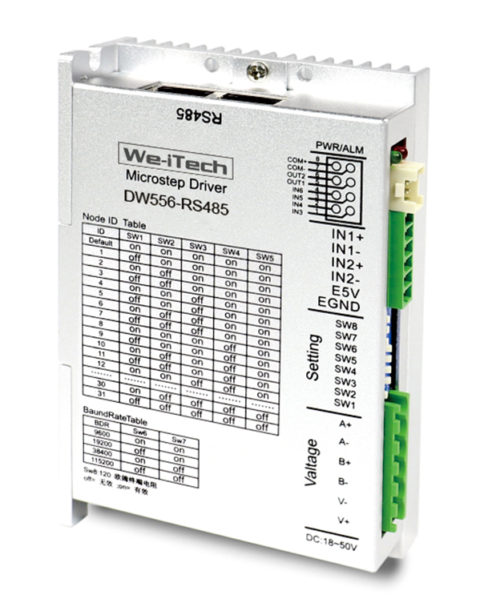

DW556-RS485

DW556-RS485 is high-performance RS485 Modbus stepper driver based on 32-bit DSP platform. DW556-RS485 integrates intelligent motion controlling function with build-in S-type motion profile. Acceleration and deceleration can be set separately. DW556-RS485 run Modbus/RTU protocol over RS485 network to control the driver and motor.

THREE-IN-ONE DW556-T DW3580-T

Three-axis platform equipment is often required to reduce space and save the cost. DW556-T/DW3580-T are the national first three-axis specific drive. DW556-T/DW3580-T can drive independently three 2/3-phrase stepper motors with frame below 60mm. The three-axis micro-stepping and the current are independently adjustable.

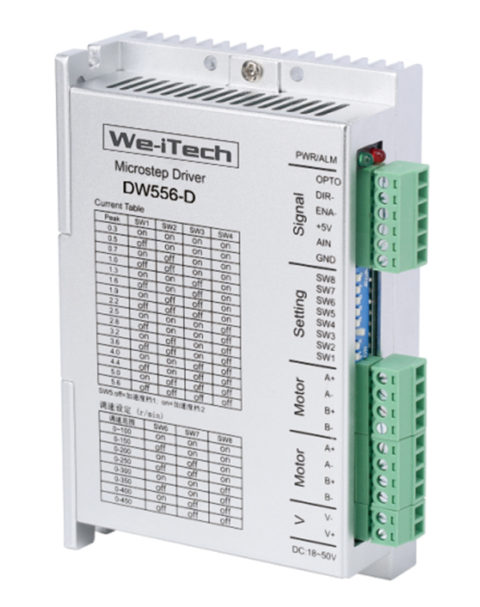

ONE-DRIVE-TWO DW556-D

Two-axis synchronization application is often required on the conveying equipment. DW556-D is the two-axis synchronization specific drive. Using the delicate dual-core DSP chip, DW556-D drives the two-axis motor independently to avoid the interference within the back electromotive force and achieve independent operation and synchronized movement.